TEN THINGS YOU NEED TO KNOW ABOUT REED VALVES

TEN THINGS YOU NEED TO KNOW ABOUT MOTORCYCLE REED VALVES

(1) Two-stroke engines suck their fuel/air mixture through the intake tract into the engine when the piston rises. This action creates a vacuum in the crankcase. On its descent, the piston forces the mixture up through the transfer ports into the combustion chamber. With earlier, piston-port engines (sans reed valves), a part of that mixture would be backwashed into the intake instead of going entirely up the transfer ports. Reed valves act as one-way check valves that prevent this backwash.

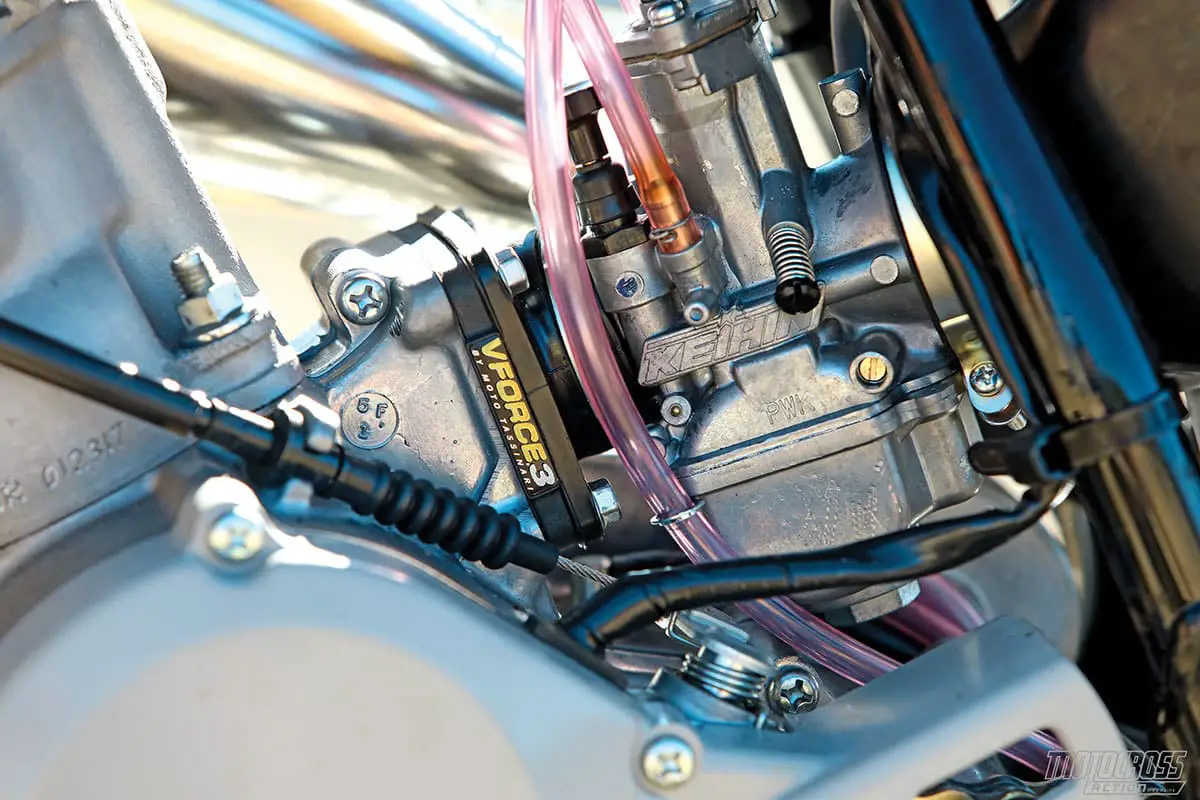

(2) A reed valve consists of flexible reed petals that sit over an opening in a wedge-shaped block. The block fits between the carburetor and the engine. With a lower pressure zone on the engine side, the reed petals flex open to allow fuel/air to pass, when the lower pressure switches to the intake tract side, the reed petals are forced tight against the reed block to seal off the intake tract.

(3) The reed petals pulse as the engine cycles, at roughly a one-to-one ratio. When the engine turns 8000 engine revolutions per minute, a reed opens 7980 times per minute. Needless to say, when the engine is running close to peak rpm, the reeds are really buzzing. With each cycle, the reed petals slap against the reed block, shortening their life span. (4) The first reeds, like GEM reeds, were made of stainless steel. These reeds were very durable and could be run a long time, but when they did break, the metal was sucked into the engine — destroying it.

(4) The first reeds, like GEM reeds, were made of stainless steel. These reeds were very durable and could be run a long time, but when they did break, the metal was sucked into the engine — destroying it.

Eventually, epoxy-based glass fiber laminate (fiberglass) reeds were developed. Fiber reeds didn’t last as long as stainless steel, but when they started to fray, they didn’t cause catastrophic damage. Carbon fiber reeds are similar to glass fiber reeds, but they are a little lighter and stiffer at the same thickness.

To achieve a compromise between lighter carbon and less expensive yet more durable glass fiber, a hybrid was developed. Manufacturers have experimented with other materials as well, including Kevlar and titanium.

(5) Durability isn’t the only advantage to different reed materials. A stronger, stiffer material allows the reed to be thinner and lighter. The lighter reciprocating mass of a reed increases performance. If the reed is too thin, however, it can start to flutter at high rpm. This means that the reed isn’t keeping up with the frequency of pulses of the engine and is disrupting airflow.

Throughout its life span, a reed petal flexes millions of times, and its individual fibers start to lose their springiness. The reed’s modulus of elasticity decreases so that in equal engine conditions the reed will deform and open farther. This is called “hang-open” and affects performance. It can even make the bike run a little richer off the bottom.

(6) In addition to thickness, a reed’s performance can be further tuned by its construction. Layup is the orientation of the plies of material of the reed. Many petals have three plies, and by laying the plies perpendicular to the area of flex, stiffness is increased. The shape of the reed’s tip can also be modified for performance. A wing-shaped tip can help air flow past it. A reed’s length affects its stiffness and the distance it must travel. (7) The specific dimensions and design of every part of the reed valve change performance. The size and shape of the overall duct of the cage, as well as the angles it may have to avoid interference with the shock, are important for airflow. Reed designers try to keep air velocity constant. The volume of the reed cage should be approximately equal to the volume in the carb and crankcase to prevent any bottlenecking. A nylon “stuffer” may be inserted into the cage to help maintain proper flow.

(7) The specific dimensions and design of every part of the reed valve change performance. The size and shape of the overall duct of the cage, as well as the angles it may have to avoid interference with the shock, are important for airflow. Reed designers try to keep air velocity constant. The volume of the reed cage should be approximately equal to the volume in the carb and crankcase to prevent any bottlenecking. A nylon “stuffer” may be inserted into the cage to help maintain proper flow.

(8) The reed block’s design can affect durability and performance. Since the reed is slapping against it over a hundred times a second, rubber or plastic can be used to cushion where the reed petal contacts the block.

(9) Moto Tassinari uses a multiple reed block design that has a larger number of shorter petals that have less distance to travel. Boyesen pioneered the dual-stage reed petal, where a smaller, lighter petal is overlaid on a longer, stiffer petal to provide a longer duration of fuel/air flow.

(10) It’s a good idea to visually inspect the reeds on a bike for fraying or chipping whenever you examine the piston rings. Boyesen and Moto Tassinari dominate the reed business. As a rule of thumb, when the MXA crew wants more midrange, we call Moto Tassinari, and when we want to increase high rpm power, we hit up Boyesen (although this is not a hard-and-fast rule).

Comments are closed.